Hydrotreating (HVO) – Concepts, feedstocks and specifications

Section: ADVANCED BIOFUELS

Series: HVO

- Hydrotreating (HVO) – Concepts, feedstocks

and specifications

- Posts: HVO

|

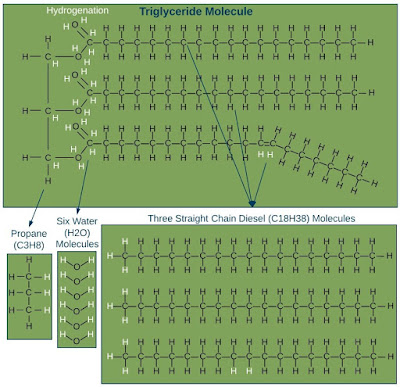

Key of the process: Treatment with hydrogen.

|

In the HVO production process, hydrogen is used

to remove the oxygen from the triglycerides producing a mix of linear

paraffins, CO2 and water. Then, the product of the first stage is

isomerized, always in presence of hydrogen, in order to branch the linear

chains for improving the cold flow properties of the final products. Thus, HVO

are mixtures of paraffinic hydrocarbons, free of sulphur and aromatics and with

a very high cetane number. The hydrocarbons created are similar to existing

diesel fuel components which allows blending in any desired ratio without any

concerns regarding fuel quality.

Figure 1. Triglyceride hidrogenation (extracted

from Reference 4)

Other term used

to refer to HVO is “Hydroprocessed

Esters and Fatty Acids” (HEFA).

Other terms used

to refer to the main HVO product are “Hydrogenation Derived Renewable Diesel” (HDRD), “Non Ester Renewable Diesel”,

“Renewable Hydrocarbon

Diesel”, “Hydro-generated

Biodiesel” (HBD), “Green

Diesel”.

The European

standard EN 15940 uses the definition ”Paraffinic Diesel Fuel from Hydrotreatment”.

|

The term HVO emerged in last decade when only

vegetable oils (e.g. rapeseed, soybean and corn oil) were used as feedstocks.

Today, more and more of HVO is produced from industrial waste (tall oil and

fats) and used cooking oils. Thus, HVO is no longer accurate describing the

origin of the fuel. However, it cannot be changed easily since it is common in

the European regulation, fuel standards and biofuel quality recommendations. Also,

“Hydrotreated” referring to fuel processing should be preferred instead of

”Hydrogenated” as the latter is commonly linked to manufacturing of margarine.

The main product of the HVO process is diesel.

However, it has to be noted that an HVO plant is a type of biorefinery and the

production of a wide range of products is possible. Apart from diesel, an HVO

facility can be used to produce jet fuel, naptha and GPLs.

Since HVO are hydrocarbons, they meet

conventional diesel fuel requirements:

- EN 15940

This standard covers also synthetic

Fischer-Tropsch products GTL, BTL and CTL. Before that, paraffinic diesel fuel

was specified by CEN Technical Specification TS 15940:2012 and CEN Workshop

Agreement CWA 15940:2009.

- EN 590, EN 16734, EN 16709

They are a family of standards published by the

European Committee for Standardization that describes the physical properties

that automotive diesel fuels B7 (EN 590), B10 (EN 16734), B20 and B30 (EN

16709) must meet if it is to be sold in the European Union and several other

European countries.

They do not take any position on how and from

what feedstock fuel is processed and allows HVO without any limit.

- ASTM D975

It is a standard for diesel fuel oils suitable

for various types of diesel engines. There are seven different grades in this

standard and renewable hydrocarbon diesel fulfil No 2-D Grade.

- The FAME specifications (EN 14214, ASTM D

6751) do not apply for HVO.

Co-processing

Part of the share of the HVO market belongs to

companies doing co-processing. It is a technique allowing for HVO production

using the desulfurization unit where vegetal oils are directly mixed with

fossil diesel. This process is much easier to implement than pure HVO

production and has also lower CAPEX. It uses the hydrogen produced in the

fossil refining units thus limiting the sourcing needs. However, it requires

the use of already refined oils which, in turns, increases the feedstock price.

At the same time, HVO is already blended into the final product so it cannot be

sold as pure HVO or used for improving the diesel quality by blending in higher

amounts.

Figure 2. Typical HydroFlex™ configuration for

co-processing of renewable and fossil feeds (extracted from Reference 5)

REFERENCES

2 H. Aatola, M. Larmi, T. Sarjovaara: Hydrotreated Vegetable Oil (HVO) as a

Renewable Diesel Fuel: Trade-off between NOx, Particulate Emission, and Fuel

Consumption of a Heavy Duty Engine. 2008 SAE International.

3 Is HVO the Holy Grail of the world biodiesel market? Greenea Team,

2014.

4 Ryze Renewables website: Technology.

5 Haldor Topsoe website: Hydroflex.