BIOREFINERY CONCEPT

Biorefinery definitions

IEA Bioenergy Task 42

Biorefinery

is the sustainable processing of biomass into a spectrum of marketable

products (food, feed, materials, chemicals) and energy (fuels, power, heat).

|

National Renewable Energy Laboratory

A

biorefinery is a facility that integrates biomass conversion processes and

equipment to produce fuels, power, and chemicals from biomass. The

biorefinery concept is analogous to today's petroleum refineries, which

produce multiple fuels and products from petroleum.

|

According

to the first definition (widely accepted), biorefinery can be a concept, a

process, a plant or even a cluster of facilities. The core is the conversion of

biomass into several product streams and the integration of various

technologies and processes in the most sustainable way.

Under

the umbrella of this definition, facilities making a more traditional use of

biomass (for instance, conventional biofuels plants and pulp and paper mills)

can be considered as simple biorefinieries. This blog is focused on advanced

biorefineries (2nd and 3rd generation) characterized for

the use of sustainable feedstocks, application of innovative biorefining

processes and, above all, high level of integration and flexibility.

Classification of the biorefineries

According

to its products

|

Energy-driven biorefineries

The

main goal is the production of one or more secondary energy carriers: fuels,

power and/or heat. Process residues are upgraded and valorised to biobased products

to maximise the economic profitability of the full biomass-to-products chain.

|

Product-driven biorefineries

The

main goal is the production of one or more biobased products: chemicals,

materials, food and/or feed. Process residues are used for the production of

bioenergy to maximise the economic profitability of the full

biomass-to-products chain.

|

According

to its technological implementation status

|

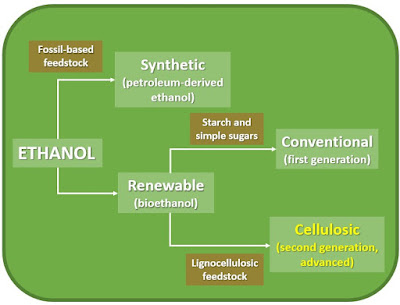

1st Generation (Simple or Conventional)

Classical

use of agricultural and forestal biomass (biomass rich on sugar: bioethanol; biomass

rich on oil: biodiesel; wood biomass: paper). Low flexibility and

integration.

|

2nd Generation (Advanced)

Lignocellulosic

biomass as raw material. Utilization of the whole feedstock. Holistic approach.

Intermediate flexibility and integration.

|

3rd Generation (Advanced)

Use

of agricultural and organic waste streams. Algal biorefinery. High flexibility

and integration.

|

According

to its size

|

Small and medium-sized production facility

Located

in rural areas. Local approach.

|

Large production facility

Linked

to a network of decentralised primary processing plants.

|

Very large production facility

Located

near a port and using mainly imported biomass.

|

According to its model

NOTE:

Criterion is not homogeneous. Some of these systems refer to the type of

feedstock while other focus on the technologies involved. The possibility to

combine different biorefinery systems by linking different technologies is

not taken into consideration.

|

|

Feedstock:

lignocellulosic biomass. Biomass is fractionated into three components:

cellulose, hemicellulose and lignin. Several final products can be obtained

from them.

|

Whole crop biorefinery

Feedstock:

cereals. Mechanical separation to remove the grain from the straw in order to

carry out a full use of the crop.

|

|

Feedstock:

green biomass. Initial fractionation by pressure to obtain two fractions: a

nutrient-rich juice organic solution and a fibre-rich lignocellulosic press

cake.

|

Two-platform concept biorefinery

Includes

sugars and syngas platforms.

|

Conventional biorefinery

Based

on existing industries (for instance, sugar or starch).

|

Thermochemical biorefinery

Based

on a mix of several thermochemical processes.

|

|

Feedstock:

aquatic biomass.

|

Liquid-phase catalytic processing biorefinery

Based

on the production of functionalized hydrocarbons from biomass-derived

intermediates.

|

Forest-based biorefinery

Based

on the use of forest biomass for simultaneous production of paper, fibers, chemicals

and energy.

|

Classification

proposed by IEA Bioenergy Task 42

|

Each

individual biorefinery system can be classified using the following four main

features:

1.

Platforms / 2. Products / 3. Feedstock / 4. Processes

A

biorefinery system is described as a conversion pathway from feedstock to

products, via platforms and processes.

See

examples in: The Biorefinery Fact Sheet (IEA Bioenergy Task 42).

|

Biorefinery Platforms

Feedstocks

Dedicated feedstocks

|

Sugar

crops: sugar beet, sugar cane, sweet sorghum…

|

Starch

crops: wheat, corn, rye…

|

Oil-based

crops: rapeseed, soya, palm oil…

|

Lignocellulosic

crops: wood, Miscanthus, short rotation poplar and willow…

|

Green

biomass: grasses, immature cereals, plant shoots…

|

Aquatic biomass: micro and macro algae.

|

Residues / Residuos

|

Oil-based

residues: animal fat from food industries, used cooking oil from restaurants

and households…

|

Lignocellulosic

residues: crop residues, saw mill residues…

|

Organic

residues and others: organic urban waste, manure, wild fruits and crops…

|

Biorefining Processes

Thermochemical

|

Combustion

|

Gasification

|

Pyrolysis

|

Torrefaction

|

Liquefaction

|

Supercritical

|

Biochemical

|

Fermentation

|

Anaerobic

digestion

|

Aerobic

digestion

|

Enzymatic

|

Chemical

|

Hydrolysis

|

Pulping

|

Esterification

|

Hydrogenation

|

Metathesis

|

Methanisation

|

Water

Gas Shift reaction

|

Mechanical and physical

|

Extraction

|

Fiber separation

|

Mechanical

fractionation

|

Pressing

and disruption

|

____________________________________________________________________________

REFERENCES

1 “IEA Bioenergy Task

42 – Brochure”. Available online: www.iea-bioenergy.task42-biorefineries.com/upload_mm/8/5/4/2e500e0f-d19a-4f7f-9360-4e9d5e580b75_Brochure%20Totaal_definitief_HR%5B1%5D.pdf (accessed

on 5th March 2016).

2 “NREL – What is a

biorefinery?”. Available online: www.nrel.gov/biomass/biorefinery.html (accessed

on 5th March 2016).

3 “IEA Bioenergy Task

42 – Factsheets Biorefineries”. Available online:

www.iea-bioenergy.task42-biorefineries.com/en/ieabiorefinery/Factsheets.htm (accessed

on 5th March 2016).

4 F

Cherubini et al.: “Toward a common classification approach for biorefinery

systems”. Published online in Wiley InterScience (www.interscience.wiley.com);

DOI: 10.1002/bbb.172; Biofuels, Bioprod. Bioref. (2009).

5 “The

European Biorefinery 2030 Vision”. Star-COLI BRI -Strategic Targets for 2020 –

Collaboration Initiative on Biorefineries.

6 “Biorrefinerías. Situación Actual y Perspectivas de Futuro”Genoma España /CIEMAT.

6 “Biorrefinerías. Situación Actual y Perspectivas de Futuro”Genoma España /CIEMAT.