Strong consortium will bring Carbios biological recycling technology to market on an industrial scale

Type of post: NEWS.

Carbios, a

green chemistry company founded in 2011, has developed two biological processes

for the breakdown and recycling of polymers in an attempt to reinvent their

lifecycle. Unlike currently used plastics recycling processes, which are

primarily thermo-mechanical, its recycling process is based on enzymes. Carbios

and L’Oréal founded a Consortium

to bring this enhanced recycling technology to market on an industrial scale in

October 2017. Committed to supporting sustainable development with innovative

solutions, Nestlé Waters, PepsiCo and Suntory Beverage &

Food Europe are joining the Consortium to promote the circular plastics

economy.

Press release: “Nestlé

Waters, PepsiCo and Suntory Beverage & Food Europe join consortium founded

by Carbios and L’Oréal to support the world’s first enzymatic technology for

the recycling of plastics”, 2/5/2019.

Under the terms of the four-year agreement, the

Consortium partners’ ambition is to bring Carbios’ PET-enhanced recycling

technology to the market and increase the availability of high-quality recycled

plastics to fulfil their sustainability commitments. The collaboration includes

technical milestones and support for the efficient supply of consumer-grade,

100% recycled PET plastics for global markets.

The enzymatic recycling

process

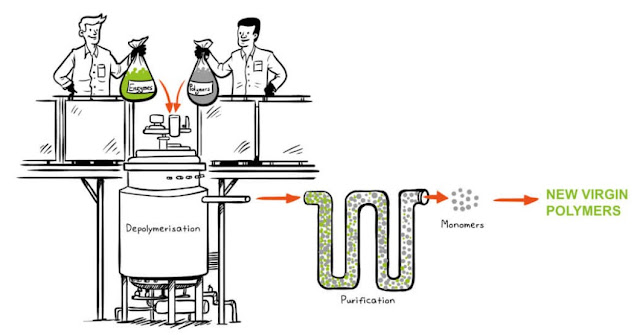

Carbios has developed an innovative process

that breaks down PET plastic waste into its original building blocks, which can

be used to produce high-quality PET plastic. This new approach enables the

specific de-polymerization of a single polymer. At the end of the first stage,

the monomer or monomers resulting from the de-polymerization process will be

purified, with the objective to re-polymerize them, thus enabling a recycling

process to infinity. Eventually, the plastic residues not degraded during the

first stage will be de-polymerized in the same way in a second stage by

applying a different enzyme that will de-polymerize other polymers in the same

way as in the first stage.

Figure 1. Carbios enzymatic biorecycling process

principle (taken from the website of the company)

This patented technology is marked by:

- Its potential to recycle PET plastics

repeatedly and rise the recycled PET content in new products (Carbios recently

achieved a world first using its enzymatic technology to create PET bottles

from 100% recycled plastics).

- Its ability to handle all forms of PET

plastics (clear, coloured, opaque and multilayer) and polyester fibres.

- A process at low temperature and pressure and

without solvents, which improves its environmental impact.

The enzymatic

biodegradation technology

Carbios is pioneering the use of enzymes to

degrade the polymers that make up plastic materials. This breakthrough

innovation involves embedding enzymes into plastic materials, thus enabling

them to fully biodegrade themselves with a controlled life span into base

molecules that can be assimilated by the microorganisms in nature.

Figure 2. Carbios “enzymated” plastics principle

(taken from company website)

Carbios founded the joint venture Carbiolice in

2016, in partnership with Limagrain Céréales Ingrédients and the SPI fund, run

by Bpifrance. This company will market the first technology licensed by Carbios

by producing enzyme pellets used in the manufacturing of biodegradable and

bio-sourced plastics. Carbiolice will target the markets of flexible films

(mulch films, bags and sacks, industrial films…) and rigid plastics (in the

field of agriculture and for disposable tableware). Theses biodegradable

plastics will meet the increasingly stringent requirements defined by France’s

energy transition law.