CRB Innovations receives grant to develop its forestry waste fractionation platform

Type of post: NEWS.

CRB Innovations (CRB), technology company based in Sherbrooke (Quebec, Canada), has received a total investment of C$8.6 million from different Canadian public agencies. The company is developing a commercial pilot project to convert forestry wastes and other biomass sources into intermediate products that will be converted into biofuels and biobased coproducts. This project is a first of its kind for Canada’s biorefining sector.

Press release: “Canada Invests in Bioenergy in Quebec”, 8/9/2020.

Figure 1. CRB Innovations receives grant to develop its forestry waste fractionation platform

The investment

The Government of Canada has invested C$4.5 million from the Natural Resources Canada’s Clean Growth Program, which supports clean technology R&D projects in Canada’s energy, mining and forest sectors. The program is a C$155-million investment fund that helps emerging clean technologies further reduce their impacts on air, land and water while enhancing competitiveness and creating jobs.

The Quebec Government has invested C$2.5 million from the Wood Innovation Program, managed by the Ministry of Forests, Wildlife and Parks, to support CRB. Because the technology demonstration project will make it possible to develop new bioproducts with a reduced carbon footprint, the Quebec government has also granted an amount of C$1.6 million under the Technoclimat Program, which promotes technological innovations in energy efficiency.

Additionally, the Clean Growth Program has provided support to CRB to collaborate with CanmetENERGY–Ottawa in the conversion of CRB mid-products to drop-in biofuels for transportation applications. This investment is made through the program’s Science and Technology Assistance for Cleantech (STAC) initiative, which provides federal laboratory support for innovators, intended to help bring Canadian clean technologies to market by providing federal research expertise, facilities and equipment.

The technology

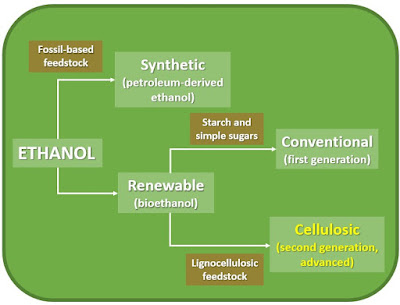

CRB has developed the FIRSST (“Feedstock Impregnation Rapid and Sequential Steam Treatment”) deconstruction and hydrolytic fractionation technology. The products are: cellulosic sugars, cellulose, furan-derivatives, lignin-derivatives and clean process residues.

The company owns a demo facility in Westbury with a processing capacity of 3.6 tons/day of wood (dry basis). The strategy pursued by the company is based on the "hub & spoke" approach: regional satellite plants produce intermediates that are upgraded to marketable products in finishing plants (the hubs) where economies of scale are reached.