NextChem and LanzaTech partner to produce renewable ethanol

Type of post: NEWS IN BRIEF.

NextChem has signed an agreement with LanzaTech for

the license of its carbon recycling process. In this way, the Italian company

will expand its circular economy and chemical recycling technology portfolio (CircularDistrict)

with the production of renewable ethanol.

Press release: “Nextchem and LanzaTech Sign an agreement to promote circular ethanol

production”, 17/7/2020.

The CircularDistrict model of NextChem,

subsidiary of Maire Tecnimont that operates in the field of

green chemistry, already had circular hydrogen and circular methanol production

technologies (currently in the engineering phase). Now, it will be also

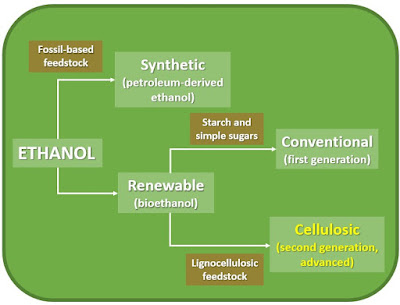

possible to obtain ethanol, an important chemical for sustainable fuels and

disinfectant production. NextChem will exclusively license this technology in

Italy and, on a project basis, in some foreign markets.

The process is based on the chemical conversion

of hydrogen and carbon contained in plasmix (non-recyclable waste from plastics

separate collection) and RDF (Refuse Derived Fuel) to generate Circular Gas that

can be used to produce various chemical products. With LanzaTech’s biological

syngas fermentation technology, ethanol is produced by bacteria, transforming

the Circular Gas at low temperature and low pressure, improving the overall

sustainability profile of the process.

The technological integration of CircularDistrict

model is among the most relevant innovations in the circular economy sector, as

it allows the generation of products such as hydrogen, methanol, ethanol, from the currently non-recyclable waste,

avoiding fossil sources and reducing climate-changing emissions.