Air Liquide, AkzoNobel, AVR, Enerkem and Van Gansewinkel to build waste-to-chemicals plant in Rotterdam

This October comes full of glad

tidings for the biorefining sector in Europe and the BR Blog is trying to stay

up to date with the latest news. Last Friday, a partnership comprised of Air Liquide, AkzoNobel, AVR,

Enerkem and Van Gansewinkel jointly announced

that it is looking to build its waste-to-chemicals plant in Rotterdam in

collaboration with the Port of

Rotterdam, the City of Rotterdam, the province of South Holland and InnovationQuarter (see press

release).

The initiative was created to

investigate how waste can be used as a raw material to produce chemicals. Specifically,

its aim is to manufacture synthesis gas from domestic and other waste and use

it as a feedstock for making the final products. The partnership studied the

options for setting up Europe’s first plant, either in Rotterdam or Delfzijl,

with the result that has just been announced. This decision marks the beginning

of a new phase for the members of the consortium who will now work together to

finalize the business case which involves the selection of the exact location

within the Port of Rotterdam and the start of the application process for the

necessary permits.

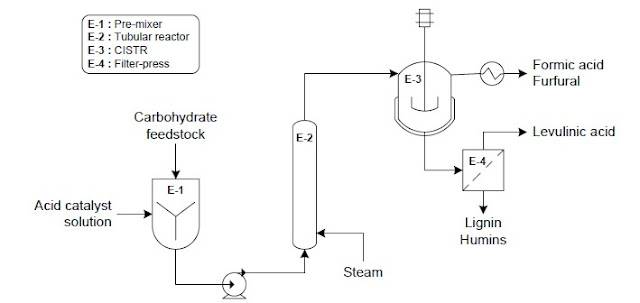

Figure 1. Diagram of the Enerkem

process (extracted from Enerkem web page)

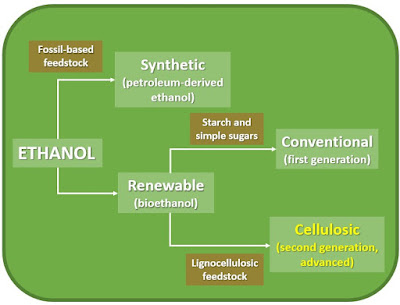

The new biorefinery will use

Enerkem’s innovative technology to convert waste into methanol. Its patented

technology chemically recycles the carbon contained in waste. The process, based

on the thermochemical platform, cover four steps:

- Feedstock preparation. Sorting, shredding, drying (if required) and feeding.

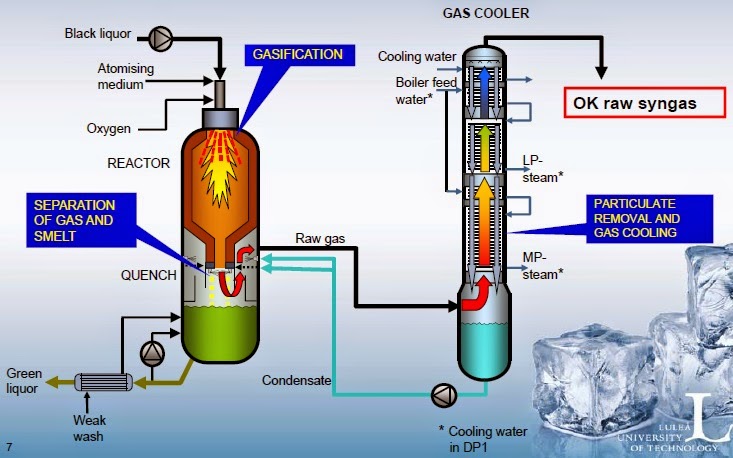

- Gasification. Conversion of carbon-rich residues into synthetic gas. In less than 5 minutes, the residues are converted into syngas.

- Cleaning and conditioning of syngas.

- Catalytic synthesis and product purification.

Enerkem’s technology has been

extensively tested and developed over the past 15 years. A commercial biorefinery

begun operation in 2015 in Alberta and was recently certified according to the

International Sustainability and Carbon Certification (ISCC) system. The

methanol will then be converted into chemicals such as acetic acid, thickening

agents and dimethyl ether.

If the consortium proceeds with the construction of

the waste-to-chemicals facility in 2017, this will represent a significant step

towards a sustainable and circular approach to waste management in Rotterdam. Enerkem’s

process is a good complement to existing recycling technologies.