Synvina (Avantium and BASF JV) – The first FDCA biorefinery is coming

Furanics have been named the

sleeping giants due to its unexploited potential as biobased chemical building

blocks for a vast range of downstream products and applications. However, it

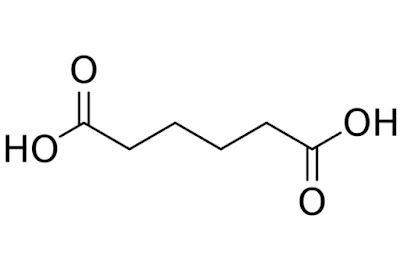

seems that the giants are awakening. Specifically, the furan-2,5-dicarboxylic

acid (FDCA) is focus of growing attention. Avantium

is leading this revolution and companies like AVA Biochem and Mercurius Biorefining are moving

pieces to occupy a good place in the chessboard. I want to prepare a

monographic post on FDCA biorefining progresses in the short term. In the

meantime, there is very good recent news to report.

BASF

and Avantium announced yesterday the formation of a new joint venture for the

production and marketing of FDCA produced from renewable resources. The name of

the JV is Synvina® and it will be headquartered in Amsterdam (The Netherlands).

It is planned to invest a medium three-digit million Euro sum to build a

reference plant with an annual capacity of up to 50,000 metric tons at BASF’s

Verbund site in Antwerp (Belgium) and to license the technology for industrial

scale production. Synvina will use the YXY process® developed by Avantium for

the production of FDCA.

Figure 1. BASF’s Verbund site in

Antwerp (Belgium). The first FDCA biorefinery will be built there

The best known application of FDCA is PolyEthyleneFuranoate

(PEF), a polyester suitable for food and beverage packaging as well as for

fibers for carpets and textiles. It is claimed to be a substitute for PET as it

offers better characteristics. For instance, improved barrier properties for

gases like carbon dioxide and oxygen and higher mechanical strength. Synvina will

also market PEF based on FDCA and continue Avantium’s established partnering

activities with leading brands (Toyobo, Mitsui, The Coca-Cola Company, Danone

and ALPLA).