Praj starts up its demo biorefinery based on Enfinity technology

Last December, the Blog reported about several agreements

to set up cellulosic ethanol biorefineries in India (see post).

Praj participates in three of them as technology

partner of two Oil Marketing Companies (BPCL and IOCL). Its second generation

ethanol platform is called Enfinity and it is based on an integrated

biorefinery approach. The company has just announced the achievement of an

important milestone regarding to the scale up of the technology: the successful

completion and start-up of its “smart biorefinery” at demonstration scale (see press release).

In 2009, Praj inaugurated the Cellulosic

Ethanol Pilot Plant at Praj Matrix (R&D centre in Urawade). Pilot plant

trials validated work done at laboratory scale. Continuing its effort in

bringing new technologies to the ethanol industry, it decided to scale up the

pilot plant and built a 2G commercial demo plant in 2012. According to some

references, the commissioning had been targeted by 2nd half 2014. However, it

is now when has been implemented.

This 2G ethanol demo plant can produce 1 ML per

year of ethanol by processing a variety of agriculture residues like rice and

wheat straw, cotton stalk, cane trash and corn cobs and stover. The process is highly

energy efficient and is equipped with zero liquid discharge system. Also, other

renewable fuels and chemicals are expected to be produced through this

technology platform. Experts from the Oil Marketing Companies and their

engineering consultants have already visited the demo plant and endorsed the

success of Praj’s technology.

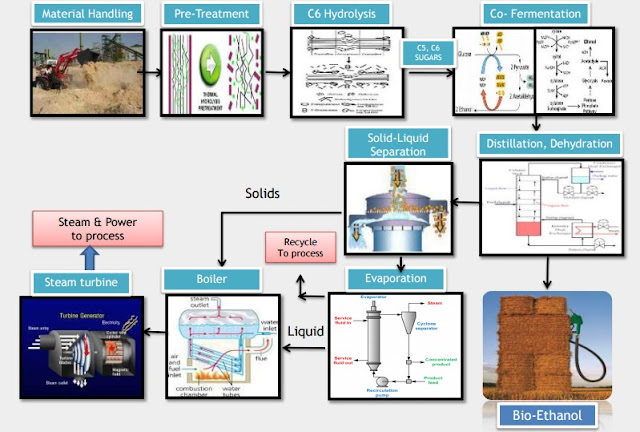

Figure 1. Praj process block diagram (extracted

from the presentation “Biomass to

Bioethanol - Second Generation Technology by Praj”, February 2016)

Talking about this achievement, Mr. Pramod

Chaudhari (Executive Chairman at Praj) said: “Commercialization of 2G ethanol

technology will give an impetus to rural economy and create additional

employment opportunities. The menace caused by burning of farm residue can be addressed

effectively by converting biomass into ethanol to be used as a transportation

fuel. Progressively increased ethanol blending will help achieve GHG emission

reduction targets agreed at COP 21 Paris summit.”

In India, an ecosystem for 2G ethanol is in the

making to attain the aspired 20% blend ratio. As a part of this drive, several 2G

ethanol projects are expected to be finalized with average CAPEX of around Rs

600 crore (approx. 85 M€). Each of these plants will have the capacity to

produce 100,000 litre ethanol per day. Praj’s smart biorefinery technology

paves the way for stepping up this ethanol blending program.