GENO BG – Genomatica unveils new biobased route to produce 1,3-butylene glycol

Genomatica

has just unveiled its latest innovation in advanced bioengineering: the GENO BGTM

process (see press

release). It is a biobased technology to make 1,3-butylene glycol (BG). In

this manner, the California-based company joins the specialty chemical space

and expands its portfolio that includes platform chemicals as 1,4-butanediol,

butadiene and polyamide intermediates.

The product

1,3-Butylene glycol, also known as

1,3-butanediol (in fact, it is one of the four stable structural isomers of

butanediol), is a four-carbon organic compound that belongs to the family of secondary

alcohols. It is used as a multifunctional emollient and humectant in skin-care

and haircare formulations and other personal care applications, as solvent in

the fragrance industry and as an additive in the food and beverage industry.

Also, it is a co-monomer in certain polyurethane and polyester resins.

Figure 1. Genomatica has begun to produce

bio-BG in 85,000 liter fermenters at EW Biotech (extracted from the press

release of Genomatica)

A new biobased route

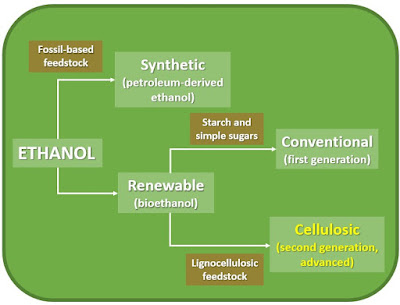

The conventional pathway to obtain BG involves

the catalytic hydrogenation of aldol using Raney nickel. The starting material

is fossil fuel-derived acetaldehyde. Genomatica’s biobased butylene glycol is

made via fermentation from plant-based ingredients. The process generates a

distinctively pure product as compared to chemistry-based process.

It has to be mentioned that Godavari Biorefineries is already manufacturing

1,3-butylene

glycol from biobased resources. However, in its case, the process is based

on acetaldehyde produced from bioethanol.

Current status of the technology

GENO BG process has been developed in stealth

and the advances are being even faster than those of 1,4-butanediol (BDO)

process. In this regard, it is noted that Genomatica’s GENO BDO process

technology is already working at commercial-scale at Novamont’s Mater-Biotech

plant. Genomatica has already produced bio-BG for sampling and has

transferred the process to 85,000 liter production fermenters at EW Biotech in Leuna (Germany).