NaturALL Bottle Alliance (Danone, Nestlé Waters and Origin Materials) to build a pioneer bio-PET plant

Important initiative driven by the packaging sector

with major implications for the growth of the biopolymers industry. Danone and Nestlé Waters, the world’s two largest

bottled water companies, have joined forces with Origin Materials, a startup based in

Sacramento (California) to form the NaturALL Bottle Alliance (see press

release). Together, the three partners aim to develop and launch at

commercial scale a PET plastic bottle made from 100% sustainable and renewable

resources. The Alliance partners consider that everyone should benefit from

this new material, demonstrating their commitment to open innovation and

sustainable business. Danone y Nestlé Waters are providing expertise and teams,

as well as financial support, to help Origin Materials make this technology

available to the entire food and beverage industry in record time. After

identifying the approach of the Californian startup separately, the two large companies

decided to team up to accelerate development of this promising technology (see the

video below).

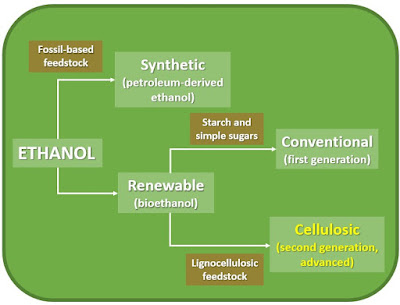

The thermoplastic polymer PET (polyethylene

terephthalate) is a product of the polymerization of monoethyleneglycol (MEG)

and purified terephthalic acid (PTA). Currently, these two monomers are almost

entirely sourced from fossil sources. To date there are a few commercial

efforts to produce bio-based MEG from ethanol. Bio-PTA, however, remains

unavailable in the market. PTA is synthesized through the oxidation of

isomerically pure paraxylene (PX).

Origin's technology produces biobased

intermediates from lignocellulosic raw materials so it does not divert

resources or land from food production for human or animal consumption. Those

intermediates can be used to make new polymers, surfactants and carbon black.

The company (formerly known as Micromidas) has developed a catalytic route to

making PX from cellulosic biomass and ethylene. The process, which involves no

fermentation, is cost-competitive with that of petroleum-derived PX.

Origin Materials has already produced samples

of 80% bio-PET in its pilot plant in Sacramento. During this year, the Alliance

will construct a pioneer plant to produce the first samples of more than 60%

bio-based PET plastic by 2018. The R&D will focus initially on cardboard,

sawdust and wood chips but other biomass materials, such as rice hulls, straw

and agricultural residue could be explored. The initial goal for the first step

is to bring 5,000 metric tons of bio-PET to the market. Thanks to the

complementary skills and shared vision of its members, the NaturALL Bottle

Alliance aims to develop the process for producing at least 75% bio-based PET

plastic bottles at commercial scale as early as in 2020, scaling up to 95% in

2022. The partners will continue to conduct research to increase the level of

bio-based content, with the objective of reaching 100%.