Construction of the Cote Nord biocrude production facility starts in Quebec

Construction has been initiated on a

10.5 million gallon (approximately, 40 Ml) per year biocrude production facility

located in Port-Cartier (Quebec). The beginning of the works for the Cote Nord project,

a biorefinery that will produce pyrolysis oil from forest residues, was

announced by Ensyn on July 13th

(see press

release). The project is being developed by Ensyn, Arbec Forest Products Inc. and Groupe Rémabec and is located adjacent to

an Arbec’s sawmill on the north shore of the St. Lawrence Seaway. The facility

is scheduled to be complete by the end of 2017 and is the first of several plants

being developed by Ensyn to expand the production of biocrude for energy

applications.

The Government of Canada suppors the project

through a $27-million investment from Sustainable

Development Technology Canada and $17.5 million from Natural Resources

Canada’s Investments

in Forest Industry Transformation program. For its part, the Government of

Quebec contributes $32 million to the project, including $10 million from Investissement Québec. In March 2016, to ensure the fibre supply, the Quebec Ministry of

Forests, Wildlife and Parks reserved 170,000 green tonnes of residues from

government forests for the plant.

Utilizing Ensyn’s proprietary RTP® technology,

the plant will convert approximately 65,000 dry metric tons per

year of slash and other forest residues from local sources to biocrude. This

product will be sold to customers in the Northeastern US and in Eastern Canada

for heating purposes and as a feedstock for petroleum refineries to produce green

transportation fuels. The RTP conversion unit is being engineered by Envergent

Technologies LLC, a joint venture between Ensyn and Honeywell UOP.

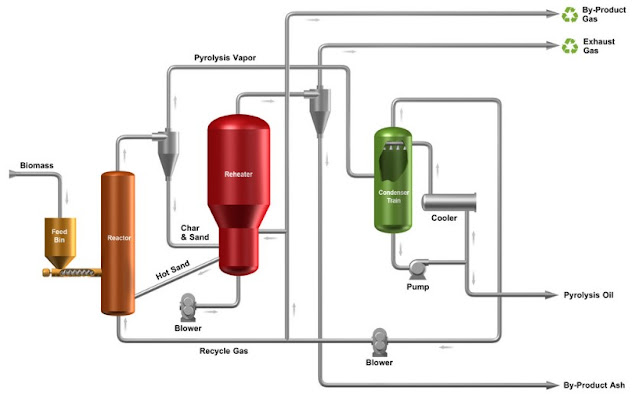

Figure 1. Simplified RTP process flow diagram

The RTP process efficiently converts a wide

range of woody biomass feedstocks (hardwoods and softwoods, forest residues and

agricultural residues) to valuable liquid fuels and chemicals. It is based on

the rapid thorough contact of hot flowing sand with biomass, which quickly

fragments the solid feedstock into vapors, gases and char. The vapors are rapidly quenched and recovered

as a light biocrude, while the gases and char flow together to a second vessel

where the sand is reheated and recirculated back to the conversion unit. Heat is recovered from the gas and char and

used to supply heat for various units of the RTP process. The by-product gas is

used as a fuel for complementary applications such as biomass drying or electrical

power generation, whereas the char is typically consumed in its entirety in the

reheater to provide the heat required to drive the process. The RTP process does not require expensive complex

catalyst systems, hydrogen or high pressure. These factors, coupled with very

short processing time, translate to attractive capital and operating costs.