Levulinic acid biorefineries

Publication date:

16/11/2015

Last update: 20/02/2016

Description 1,2

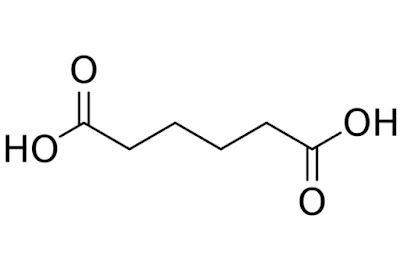

Levulinic acid (also

known as 4-oxopentanoic acid or γ-ketovaleric acid) is an organic compound with

chemical formula C5H8O3. It is a white

crystalline solid soluble in water and polar organic solvents. It contains

ketone and a carboxylic group whose presence results in interesting reactivity

patterns. It is one of the more recognized Biobased

Chemical Building Blocks, a starting material for a wide number of

compounds (see Applications below). In fact, it was recognized by the US DoE as

one of the top biobased platform chemicals of the future and it can

successfully address many performance-related issues attributed to

petroleum-based chemicals and materials.

Process

technologies 1,3,4,5

The controlled

degradation of C6-sugars by acids is the most widely used approach to prepare

levulinic acid from lignocellulosic biomass. Other methods have also been

studied, for instance, the hydrolysis of acetyl succinate ester, the acid

hydrolysis of furfuryl alcohol and the oxidation of ketones. However, these

methods require expensive raw materials and result in relatively high amounts

of by-products.

Acidic hydrolysis

of lignocellulose (a simple thermochemical process) causes the breakdown of

polymer sugars to both C5 and C6 sugars. A degradation product of C6 sugar is

5-hydroxymethylfurfural (HMF), a furan compound that can be converted (via

hydration) to levulinic acid and formic acid in equimolar amounts. Dehydration

of C5 sugars (hemicellulose fraction) results in furfural, which can be delivered

as a product or upgraded to levulinic acid. Lignin along with some degraded

cellulose and hemicellulose and any inerts, comes out of the process as a

carbon-rich char mixture. Many concepts for the commercial production of

levulinic acid are based on this strong acid technology. Companies who

developed process based on this model are: Biofine, DSM, GFBiochemicals and Segetis (acquired by the previous one).

Figure 1. Continuous

production of levulinic acid by the Biofine Technolgy (extracted from Reference

1)

Applications 6,7,8

Levulinic acid can

serve as an incredibly versatile building block for chemicals and materials

derived directly from biomass. It is used as a precursor for:

- Fuel additives. Levulinate esters are additives for gasoline and diesel transportation fuels. For instance, they can replace current cetane improvers and cold-flow performers for diesel. They may also replace lubricity improvers. Methyltetrahydrofuran (MeTHF), a levulinic acid derivative, can also be blended up to 50% with gasoline to increase vehicle performance and reduce air emissions.

- Solvents. Levulinic acid esters, gammavalerolactone (GVL) and MeTHF are suitable solvents for a number of applications. GVL can replace ethyl acetate and MeTHF can be used as a substitute of tetrahydrofuran (THF) in the fine chemical and pharmaceutical industry.

- Polymers and plasticizers. Levulinic acid-derived ketal esters can replace major phthalate-based plasticizers. Methyl butanediol (MeBDO) has potential as a monomer for polyurethanes. GVL can be a monomer for polyester-polymers and starting materials for pyrrolidinone-isomers.

- Resins and coatings. Levulinic acid can be used in polyester resins and polyester polyols to increase scratch resistance for interior and exterior coatings. Its derivative Diphenolic Acid (DPA) is used in protective and decorative finishes.

- Agro-chemicals. Its derivative delta-amino levulinic acid (DALA) is used as an herbicide on lawns and certain grain crops.

- Pharmaceuticals. Levulinic acid is used in anti-inflammatory medication, anti-allergy agents, mineral supplements and transdermal patches. DALA is used for diagnosis and treatment of cancer.

- Personal care. Levulinic acid and its derivatives are used in organic and natural cosmetic compositions for antimicrobial, perfuming, skin conditioning and pH-regulating purposes.

- Flavors and fragrances. Levulinic acid esters are often used as niche fruity flavor and fragrance ingredients.

Figure 2.

Levulinic acid as platform chemical (extracted from Reference 8)

Commercial plants

- Operational 9,10

Caserta

Biorefinery

|

|

Owner

|

GFBiochemicals (www.gfbiochemicals.com)

|

Location

|

Caserta (Italy)

|

Feedstocks

|

Cellulosic feedstock.

|

Technology

|

Proprietary technology platform. Thermochemical

conversion: acidic

hydrolysis of lignocellulose. Recovery and purification

of levulinic acid. Formic acid and char are recovered.

|

Capacity

|

10,000 tons per year (scale up to

full capacity by 2017).

|

Start-up

|

July 2015.

|

Note

It does exist an

unorganized market in China. It was not possible to find information about the

plants of the suppliers: Hebei Langfang Triple Well Chemicals, Hebei

Shijiazhuang Worldwide Furfural & Furfuryl Alcohol Funan Resin, Jiangsu

Yancheng China Flavor Chemicals, Shijiazhuang Pharmaceutical Group Ouyi

Pharmaceutical, Shanghai Apple Flavor & Fragrance and Shandong Zibo Shuangyu

Chemical.

Commercial plants

– Under construction or planning 11

Location

|

Companies

|

Capacity

|

Status

|

To

be determined

|

Segetis (www.segetis.bio).

JavelinTM

technology.

Note: Segetis has

been acquired by GFBiochemicals.

|

15

ktons/y

|

Planned

for 2017.

|

Pilot and

demonstration plants 3,11

Location

|

Companies

|

Capacity

|

Status

|

Golden

Valley (MN, USA)

|

Segetis (www.segetis.bio).

Note: Segetis has

been acquired by GFBiochemicals.

|

-

|

Demonstration

plant. Fully operational since 2012.

|

Gorham

(ME, USA)

|

Biofine

Technology (www.biofinetechnology.com)

|

-

|

Demonstration

plant. Operational since 2014.

|

Limerick (Ireland)

|

DIBANET Project (www.dibanet.org).

|

6 kg/h of biomass

(processed)

|

Pilot plant. No

longer operational.

|

San

Fernando de Henares (Madrid, Spain)

|

LIFE + WALEVA

project (www.waleva.eu).

Partnerchip: Técnicas Reunidas, CICYTEX and FEIQUE.

|

1 ton/month of

dry rice straw (processed).

|

Pilot plant.

Expected to be operational by Q4 2016.

|

_________________________________________________________________________________

REFERENCES

1 B. Girisuta: “Levulinic Acid from Lignocellulosic Biomass”.

PhD Thesis. November 2007.

2 T. Werpy, G.R.

Petersen: “Top Value Added Chemicals from

Biomass. Volume 1: Results of Screening for Potential Candidates from Sugar and

Systhesis Gas”. US DoE, August 2004.

4 “Bio-Based Chemicals: Value Added Products

from Biorefineries”. IEA Bioenergy, Task 42 Biorefinery.

5 P. Harmsen, M. Hackmann: “Green Building Blocks for Biobased Plastics”.

Wageningen UR Food & Biobased Research, March 2013.

10 http://www.radiantinsights.com/research/levulinic-acid-market-analysis-and-segment-forecasts-to-2020.

11 http://www.segetis.bio/technology/#javelin.