BioTfueL project – 2G biofuels via thermochemical conversion

PROJECT FACTSHEET

Partners

|

|

Budget

|

€112.7 million (€33.3 million in public

funding)

|

Feedstocks

|

Lignocellulosic biomass (straw, forest waste,

dedicated energy crops)

|

Platform

|

Termochemical - Syngas

|

Technologies

|

Torrefaction, gasification and Fischer-Tropsch

synthesis

|

Products

|

Renewable diesel and jet fuel

|

Capacity target

|

200,000 metric tons per year

|

Date for market launch

|

2020

|

Location of the demonstration units

|

Pretreatment: Sofiprotéol’s site in Venette (France).

Gasification, purification and synthesis:

Total’s site in Dunkirk (France).

|

GENERAL INFORMATION

Total is working in two large

projects for retrofitting its conventional facilities with biorefining

technologies. The first one is the transformation of the La Mède refinery into

a HVO (Hydrotreated

Vegetable Oil) plant. The plans were unveiled in April 2015 and entail an

investment of €200 million to produce 500,000 metric tons per year of

high-quality renewable diesel. The second one is the initiative covered by this

post: the BioTfueL project.

BioTfueL, launched by Total and five

partners, is focused on developing and marketing an end-to-end chain of technologies

for converting biomass into second-generation biofuels via thermochemical

conversion. The process can also convert fossil feedstock mixed with biomass to

ensure a continuous supply despite seasonal variations in biomass availability.

The high quality biofuels produced using this process chain will be free of

sulphur and aromatic compounds and technically suitable for use in all types of

diesel and jet engines. The partners’ goal is to produce 200,000 metric tons of

renewable diesel and jet fuel per year from one million metric tons of biomass

by 2020. The BioTfueL project also examines the possibility of locating

pretreatment units in regions that have an abundant supply of biomass, so as to

densify biomass material early on in the production process.

After five years of R&D, the

project entered a new phase with the construction of the demonstration units

that are expected to come on stream later this year. The pretreatment will take

place at Sofiprotéol’s site in Venette whereas the subsequent process steps will

be performed at Total’s site in Dunkirk. The demonstration units will validate

the technical and economic feasibility of the technologies and optimize their

energy efficiency and environmental impact. On completion of the project, the

process chain will be ready for the transition to industrial-scale production.

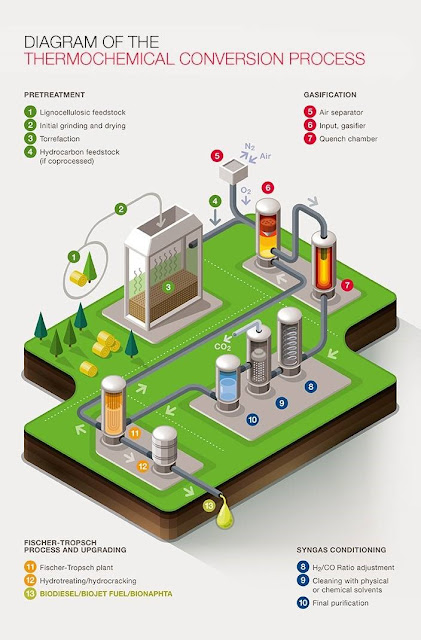

Figure 1. BioTfueL process (extracted from Total web page)

THE PROCESS

1. Biomass pretreatment

The biomass is pretreated, dried and

pulverized so that it can be injected under pressure into a gasifier via

fluidization and pneumatic conveying. The specific pretreatment to be used is

the torrefaction, a mild thermal process (250-300ºC) at inert atmosphere and atmospheric

pressure and with a residence time between 20 and 60 minutes. The product obtained

must be easy to grind without facing considerable mass losses and homogeneous.

2. Gasification

Once the pretreated biomass has been

ground into a powder, it is transported to the gasifier. There, it is exposed

to very high temperatures (1,200 - 1,600ºC) in the presence of oxygen to

convert it into syngas. The gasification reactions take place under a pressure

of 30 - 42 bar and achieving a conversion of more than 99% takes less than two

seconds. A pressurized entrained-flow gasifier has been selected because it

offers high levels of treatment capacity, great flexibility in terms of

feedstock and a very pure syngas. The synthesis gas leaves the reactor at the

bottom and it is cooled down by a water quench to about 220ºC. This gasification

technology of ThyssenKrupp Industrial Solutions (PRENFLO)

is already used commercially to treat fossil fuel feedstock. However,

significant changes are required to enable the injection of biomass into the

gasifier, either alone or mixed with fossil fuel feedstock in varying

proportions.

3. Syngas clean up and conditioning

To be converted into liquid fuel,

the syngas must be very pure and have the correct chemical composition. Indeed,

the syngas produced in the gasifier has a low H2/CO (0.5-0.7) ratio

when compared with the requirement of the Fischer-Tropsch (FT) reactor (almost

2), hence Water Gas Shift (WGS) reaction is performed on a part of the syngas. The

CO2 formed is removed with H2S and other impurities using

an Acid Gas Removal (AGR) unit. Since the FT catalyst requires very low levels

of impurities, a final purification step is performed with guard beds (chemisorption).

4. Fischer-Tropsch (FT) synthesis and upgrading

The FT process converts purified

syngas into a mixture of hydrocarbons. This step is followed by hydrocracking

and hydro-isomerization stages in order to get final products: mainly middle

distillates (diesel and jet fuel) and naphtha. Unlike the first three stages

described above, no R&D work will be carried out on the FT process during

the BioTfueL project, because this process is already available commercially.

The technology is the GaselTM

process (developed by IFP Energies nouvelles, ENI and Axens). This technology

involves a cobalt catalyst, maximizing the production of middle distillates

into a slurry bubble column reactor.

_________________________________________________________________________________

REFERENCES

1 www.total.com/en/energy-expertise/projects/biomass/biotfuel-converting-plant-wastes-into-fuel

(accessed on 13rd June).

2 www.ifpenergiesnouvelles.com/News/Specific-issues/Second-generation-biodiesel-and-biojet-fuel-IFPEN-partner-of-BioTfueL-project

(accessed on 14th June).

3 J.-C. Viguié et al.: “BioTfueL Project: Targeting the Development of Second-Generation

Biodiesel and Biojet Fuels”. Oil & Gas Science and Technology – Rev.

IFP Energies nouvelles, Vol. 68 (2013), No. 5, pp. 935-946.